Stove Burner Stays on High No Matter What? Here is the Fix

Safety Alert: Immediate Action Required

If your stove burner stays on high even when the dial is set to “Low” or “Off,” you are dealing with a Thermal Runaway event. This is a fire hazard. Do not attempt to “wait it out.”

- Turn off the burner knob immediately.

- If the burner remains red hot, flip the circuit breaker labeled “Range” or “Stove” in your electrical panel (usually a double-pole 40A or 50A breaker).

- Do not turn the power back on until you have read this guide.

You put a pot of soup on to simmer. You turn the dial to “Low” (setting 2). Five minutes later, the soup is boiling over violently, and the heating element is glowing cherry red like you set it to “Max.”

I see this panic-inducing failure mode constantly in my repair calls, especially during the holiday season. The good news? Your expensive glass cooktop or heating element is likely fine. The bad news? The control component behind the knob has suffered a catastrophic mechanical failure.

In this guide, we will bypass the generic advice and drill down into the specific component failure—the Infinite Switch—that causes a stove burner to lock into the “High” position. We will cover how to identify the specific type of control you have (Analog vs. Digital) and explain exactly why turning the knob is doing absolutely nothing.

The “Why”: It’s Rarely the Heating Element

A common misconception DIYers have is assuming the heating element itself is “shorted out” or “broken on.”

They are simple resistors. They do not decide when to turn on; they only do what they are told. If an element is getting 240V of electricity continuously, it is because the “brain” (the switch) is screaming “GO” without taking a breath.

The “Infinite Switch” Mechanism Explained (The Bi-Metal Strip)

Most electric ranges (both coil and glass top with knobs) use what we call an Infinite Switch. It is not a dimmer switch (rheostat) like you have on your dining room wall. It is a thermal cycler.

How it normally works:

When you turn the knob to “Medium” (5), the switch sends 240V to the burner and to a tiny Bi-Metal Strip inside the switch itself.

- The burner heats up.

- The internal bi-metal strip heats up.

- As the strip gets hot, it bends (deforms) and physically “clicks” the contact open, cutting power to the burner.

- The burner cools down. The strip cools down and snaps back, reconnecting the power.

This cycle happens continuously. On “Low,” the strip heats up fast and cuts power quickly (10% on, 90% off). On “High,” the strip is bypassed, and power flows 100% of the time.

Why Turning the Knob Does Nothing (The “Welded Contact” Failure)

So, why does your stove burner stay on high?

Over years of cooking—especially heavy canning or boiling large stockpots—the electrical contacts inside that switch open and close thousands of times. Every time they separate, a tiny electrical arc (spark) occurs. This creates carbon buildup and pitting.

Eventually, one of two things happens:

- The Bi-Metal Fatigue: The strip loses its springiness and can no longer push the contacts apart.

- The Contact Weld (Most Common): The contacts get so hot from resistance that they physically melt and fuse together.

When the contacts weld, the switch becomes a solid wire. It doesn’t matter if you turn the knob to “Low” or “Simmer.” The mechanical bridge inside is fused shut. The electricity has a direct, uninterrupted highway to your heating element, locking it at maximum temperature.

Tech Tip: If you listen closely to a working burner, you hear a rhythmic click… click every few seconds. If your burner is stuck on high, that clicking sound is gone.

Digital vs. Analog: Is it a Switch or a Relay Board?

Before we start ripping panels off, we need to confirm what controls your burner.

- Analog Rotary Knobs (The Infinite Switch)

If your stove has physical knobs that you turn, you almost certainly have an Infinite Switch. This applies to:

- Standard Coil Ranges (Whirlpool, GE, Kenmore).

- Glass Top Ranges with knobs.

- Digital Touch Panels (The Relay Board)

If you press a button on a glass surface to select “Simmer” and the burner goes to “High,” you do not have an infinite switch. You have a Main Control Board with electromechanical relays.

- The Failure: The relay is a small black box on the circuit board. Inside, a magnetic arm pulls a contact closed. If that arm gets stuck or the contact welds (just like the switch), the relay stays “Latched.”

- The Fix: You usually cannot replace just the relay unless you are skilled at board-level soldering. You typically have to replace the entire control board.

Quick ID: What System Do You Have?

| Feature | System Type | Likely Failure Part | Repair Difficulty |

| Physical Knobs | Analog Control | Infinite Switch | Medium (DIY Friendly) |

| Touch Buttons | Digital Control | Relay Board | Hard (Expensive Part) |

| Hybrid (Knobs + Digital Display) | Hybrid | Potentiometer or Infinite Switch | Check Schematic |

What Common Advice Gets Wrong (Safety Guardrails)

If you Google this problem, you will see generic advice that can be dangerous or wasteful. Let’s correct the record before you buy parts.

Myth 1: “It’s the Thermostat.”

- Reality: Surface burners (the rings on top) do not have thermostats. A thermostat measures temperature (like in your oven). Surface burners operate on time-based duty cycles, not temperature. Searching for a “stove top thermostat” will lead you to the wrong parts.

Myth 2: “Just buy a Universal Switch on Amazon.”

- Reality: I strongly advise against “Universal” infinite switches for DA 15 websites or novice DIYers.

- Shaft Length: Universal shafts often need to be cut to size, which is easy to mess up.

- Amperage: A small 6-inch burner draws ~1200 watts. A large 8-inch or dual burner draws ~2500+ watts. If you put a switch rated for a small burner on a large burner, it will melt within weeks.

- Wiring: Universal switches often require you to re-map the wiring (H1 to L2, etc.). If you get this wrong, you cause a direct short.

Myth 3: “Unplug it and it resets.”

- Reality: This works for confused software (glitchy control boards). It does not fix a welded mechanical contact. If two pieces of metal are melted together inside a switch, unplugging the stove won’t separate them.

Preventative Actions & Summary

Before moving to the Diagnostic Phase (Section 2), confirm the following:

- You have identified if you have Knobs (Infinite Switch) or Touch (Relay).

- You have verified the specific burner that is failing.

- You have located your stove’s model number (usually on a sticker behind the drawer or on the frame when you open the oven door).

Diagnostic Phase: Isolate the Failure

Safety Alert: High Voltage (240V)

Before proceeding with any physical checks, you must disconnect power.

- Turn off the circuit breaker labeled “Range” or “Stove.”

- If you can access the plug (often behind the drawer or by pulling the stove out), unplug the unit.

- Verify No Power: Turn on a working burner. If it does not heat up or click, power is off.

In Section 1, we established that a “welded contact” inside the Infinite Switch is the most likely culprit. Now, we need to prove it. Before you order a $40–$80 replacement part, we will use two simple tests to confirm the diagnosis.

The “Percussive Diagnostic” (The Tap Method)

This sounds crude, but it is a legitimate first step used by seasoned technicians to confirm a “stuck” mechanical contact.

The Theory:

Inside the switch, the bi-metal strip pushes against a spring-loaded contact arm. Over time, carbon buildup from arcing acts like glue, making the contacts stick together even when they should spring apart. A sharp physical shock can sometimes break this temporary bond.

The Test:

- Power ON: Turn the breaker back on for this test only.

- Turn the Knob: Set the problem burner to “Low” (2-3).

- Observe: If the element glows bright red immediately (full power), proceed.

- The Tap: Using the handle of a screwdriver (plastic end), give the knob a firm, sharp rap or tap. Do not smash it, but hit it hard enough to jar the internal mechanism.

- Result:

- Click! If you hear a click and the burner cycles off (stops glowing red), you have confirmed a Mechanical Stick. The switch is failing and must be replaced, but you have proven the circuit is otherwise fine.

- No Change: If the burner stays red hot, the contacts are welded solid. The switch is dead.

Why do this?

It rules out a “Wiring Short.” If tapping the switch changes the behavior at all, the problem is definitely inside that switch box. If the burner stays on high no matter what you do to the knob, it could (rarely) be a shorted wire elsewhere.

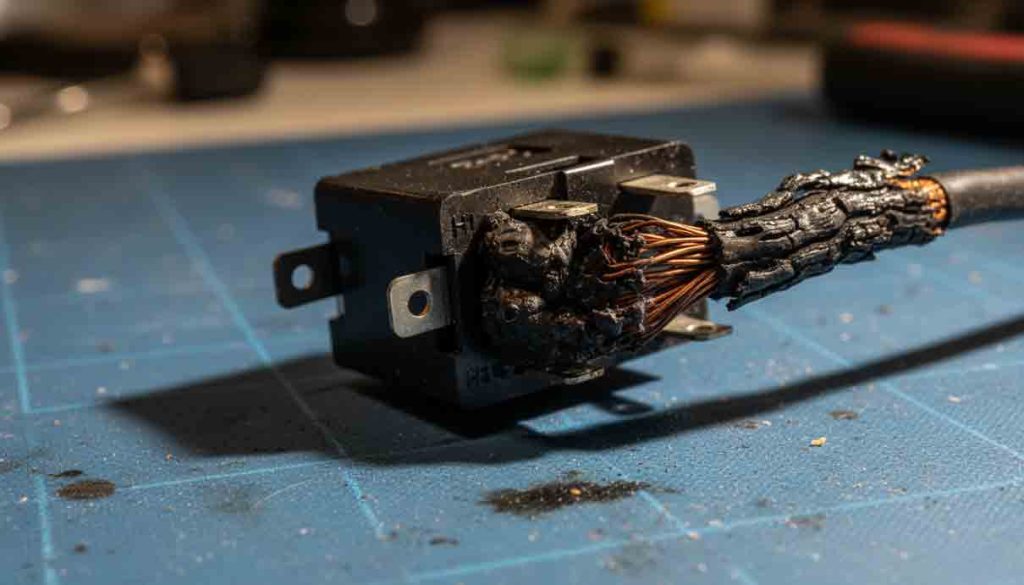

Visual Inspection: Melted Wires & Charred Terminals

Now, cut the power again (Breaker OFF). We need to look at the switch itself.

Accessing the Switch:

- Rear Console (Most Common): Remove the screws on the back of the upper control panel (usually 1/4″ hex head or Phillips). Tilt the back panel forward or lift it off.

- Front Panel (Slide-In Ranges): You may need to remove the knobs first, then unscrew the bezel or manifold panel behind them.

What to Look For:

Locate the switch corresponding to your bad burner. Compare it to the others.

- The “Flash” Mark: Look for black soot or scorch marks on the switch body, especially near the wire terminals. This indicates a high-voltage arc occurred.

- The “Crispy” Wire: Check the wire insulation connected to the H1 and H2 terminals. Is it discolored, brittle, or melted?

- The Melted Terminal: Sometimes the plastic housing around the spade terminal melts, allowing the terminal to wiggle loose. This creates high resistance and heat, welding the contacts internally.

Tech Tip: If the wire terminal is burnt, you cannot just put a new switch in. You must cut the damaged wire back to clean copper and crimp on a new high-temperature spade connector. Using a burnt wire on a new switch will destroy the new switch in days.

Multimeter Test: Continuity Check (The Definitive Proof)

If the visual check is inconclusive, a multimeter is the final judge. You can get a cheap one for $15–$20.

Setting Up:

- Set your multimeter to Continuity Mode (looks like a sound wave or WiFi symbol) or Resistance/Ohms ($\Omega$).

- Touch the probes together. You should hear a beep or see 0.0 on the screen.

The H1 to H2 Test:

The Infinite Switch has several terminals, but the critical ones for the heating circuit are usually labeled H1 and H2 (Heater 1 / Heater 2). On some switches, these are L1 and L2 (Line 1 / Line 2) input vs H1/H2 output.

Consult your stove’s wiring diagram (usually in a plastic pouch on the back of the stove).

- Isolate the Switch: Disconnect the wires from the switch (take a photo first!).

- Knob OFF: Turn the switch knob to the OFF position.

- Probe H1 & H2: Touch one probe to the H1 terminal and one to the H2 terminal (or L1 to H1).

- Expected: OL (Open Loop) or Infinite Resistance (No beep). The switch is Off; no power should flow.

- Failure: 0.0 – 1.0 $\Omega$ (Continuity / Beep).

- Diagnosis: If you have continuity (a beep) between the power input and heater output while the knob is OFF, the switch contacts are welded shut. The switch is permanently “On.”

The Dual-Element Twist:

If you have a dual burner (inner/outer rings), you likely have a 5-wire switch.

- These switches have a separate contact for the outer ring.

- Test continuity between the L2 (Line 2) and the generic “Element” terminal (often just a number or color code).

- If the outer ring stays on high but the inner works fine, test the specific contact pair for the outer element. A beep on “Low” setting (when it should be cycling) confirms the failure.

Data Table: Troubleshooting the “Infinite Switch”

| Test Step | Action | Result A (Normal) | Result B (Failure) |

| 1. Percussive Test | Tap knob with handle | No change (if working) | Burner cycles off (Stuck Contact) |

| 2. Visual Check | Inspect terminals | Clean brass/silver | Black soot / Melted plastic |

| 3. Continuity (OFF) | Probe H1-H2 (Knob OFF) | OL (No Beep) | 0.0 $\Omega$ (Beep) -> WELDED |

| 4. Continuity (LOW) | Probe H1-H2 (Knob LOW) | Cycling (Beep… No Beep) | Constant Beep -> WELDED |

Preventative Actions & Summary

At this point, you should have 100% confirmation that your Infinite Switch is the culprit.

Validated the failure with the “Tap Test” or Visual Inspection.

Confirmed “Continuity on OFF” with a multimeter (Optional but recommended).

Noted the Part Number printed on the switch body (e.g., WB24T10025 or 316436000).

Do NOT buy a generic “Universal” switch yet.

In Section 3, we will cover the exact steps to replace the switch, how to handle the “Wire Transfer” so you don’t mix up L1/L2 (and cause a dead short), and why buying the specific OEM part is critical for safety.

Step-by-Step Repair: Replacing the Infinite Switch

Safety Check: Verify Power is OFF

Before touching a screwdriver, ensure the breaker is flipped. Test the stove controls one last time. If the clock is on or a burner lights up, STOP. Find the correct breaker.

This is the final phase. We have confirmed the Infinite Switch is the culprit. Now we replace it.

Tools You Need:

- #2 Phillips Screwdriver (Magnetic tip helps).

- Needle-Nose Pliers (For stubborn wire terminals).

- Work Light / Headlamp.

- Camera / Phone (Crucial step!).

- New Infinite Switch (Exact OEM Part Number match).

Accessing the Switch (Rear Console vs. Front Panel)

Most electric ranges have the controls on a backguard panel.

- Pull the Stove Out: Slide the range away from the wall about 6-12 inches. Be careful of the floor (use cardboard sliders).

- Remove the Back Panel: Locate the ¼” hex or Phillips screws along the top and sides of the rear console.

- Tip: Do not remove the screws holding the power cord block (bottom center). Just the upper control panel.

- Tilt & Support: The panel might be hinged or lift off entirely. Support it so wires aren’t strained.

- Locate the Bad Switch: It will be directly behind the knob you identified as faulty.

Front Control / Slide-In Ranges:

- Remove the knobs first.

- Unscrew the locking rings or bezel nuts under the knobs.

- Remove the screws under the front lip (open the oven door to see them).

- The manifold panel should tilt forward.

The “Wire Transfer” Method (Don’t Rely on Wiring Diagrams)

CRITICAL STEP: Do not unplug all the wires at once!

Stove wiring can be confusing. Colors change between models. The positions on the new switch might be rotated 90 or 180 degrees compared to the old one.

The Golden Rule: Transfer wires one by one.

- Orient the New Switch: Hold the new switch next to the old one. Look for the terminal labels: L1, L2, H1, H2, P.

- Note: The physical location might be different, but the labels are what matter.

- Transfer L1: Pull the wire off the L1 terminal of the old switch. Plug it immediately onto the L1 terminal of the new switch.

- Transfer L2: Repeat for L2. (This is usually the other main power wire).

- Transfer H1 & H2: These go to the heating element. Move them one by one.

- Warning: Do not swap H1 and L1! This will cause a direct short when you turn the power on.

- Transfer P (Pilot): This small wire powers the “Burner On” indicator light. Move it last.

Visual Check:

- Are all connections tight? A loose spade terminal creates heat and will melt your new switch.

- If a connector is loose, squeeze it gently with pliers before sliding it on.

- Did you break any wire insulation? Wrap with electrical tape if minor; replace the terminal if copper is exposed.

Single vs. Dual Element Switch Wiring (The Critical Difference)

If you are replacing a switch for a Dual Burner (Inner/Outer rings), pay extra attention.

- 5-Wire Switches: You will have an extra terminal, often labeled with a specific number or symbol for the “Outer Element.”

- The “Jumper”: Some universal switches require you to install a small metal jumper wire (included in the bag) between two terminals. Read the instruction sheet carefully. If you miss this, the outer ring won’t work.

- OEM is Safer: This is why I recommend OEM (Original Equipment Manufacturer) parts. They come pre-configured. No jumpers, no guessing.

Reassembly & The “Smoke Test”

- Mount the Switch: Screw the new switch into the control panel. Hand-tighten the screws—do not crack the plastic.

- Knob Alignment: Put the knob back on. Does “Off” point to 12 o’clock? If it points to 3 o’clock, you mounted the switch upside down or the shaft is different. (This is annoying but not dangerous).

- Close the Panel: Secure the back panel with its screws.

- Power ON: Flip the breaker back on.

The Test:

- Turn to Low: Turn the knob to “Low” (Setting 1 or 2).

- Observe:

- Pass: The element glows faintly or pulses on/off. The “Burner On” light is lit.

- Fail: The element instantly goes to High (Bright Red). Turn off immediately! You likely have a shorted wire or a defective new part.

- Fail: Sparks/Pop! Turn breaker off. You likely crossed L1 and H1. Re-check wiring.

Preventative Actions Checklist

To stop this from happening again next Thanksgiving:

- Clean Your Switches: Once a year, pull the knobs off and blow out any dust/lint with compressed air.

- Don’t “Oversize” Pots: Using a massive stockpot on a small burner reflects heat back into the glass/coil, overheating the switch and wiring. Match the pot size to the burner ring.

- Listen for the “Click”: Periodically listen to your burners on “Low.” If you don’t hear them cycling (clicking), the switch is starting to stick. Replace it before it fails completely.

Frequently Asked Questions

Q: My new switch shaft is too long!

A: You bought a “Universal” switch. These have “break-off” shafts. Use two pairs of pliers to snap the shaft at the indented groove that matches your old one. Be careful not to bend the internal mechanism.

Q: The “Burner On” light stays on all the time now.

A: You likely swapped the P (Pilot) wire with the L1 or L2 wire. The pilot circuit is now getting constant power. Double-check the labels. P goes to P.

Q: Can I repair the old switch?

A: No. The bi-metal strip is calibrated at the factory. Once opened, you destroy that calibration. Plus, you cannot reliably un-weld the contacts. It is a sealed, disposable component.

Q: Where is the best place to buy an OEM switch?

A: Avoid generic Amazon sellers (“UpStart Components,” etc.) for this part. Go to RepairClinic, AppliancePartsPros, or Sears PartsDirect. Look for brands like Robertshaw, EGO, or the genuine GE/Whirlpool bag.

Q: My multimeter beeps on everything. Am I doing it wrong?

A: Make sure you are testing the switch terminals, not the wires. Disconnect at least one wire from the terminal you are testing to ensure you aren’t reading “back-feed” through the rest of the stove’s circuitry.

Q: Can I just clean the contacts with sandpaper?

A: No. These contacts are plated with special alloys to resist arcing. Once they weld or pit significantly, the plating is gone. Filing them down exposes base metal, which will oxidize and weld again within days—often worse than before.

Q: The wires are stuck on the terminals. How do I get them off?

A: This is common due to heat cycling. Use needle-nose pliers. Grip the spade connector (the metal part), not the wire insulation. Wiggle it gently side-to-side while pulling. Do not yank the wire, or you’ll rip it out of the crimp.

Q: Can I keep using the other burners if one is stuck on high?

A: technically, yes—if you are careful. However, I do not recommend it. If one switch has failed due to age/voltage spikes, the others are likely close to failure. Also, if the “stuck” switch is shorting internally, it poses a shock hazard even if the knob is Off. It is safer to flip the breaker until fixed.

Q: Why does the burner stay hot even when I turn the knob to OFF?

A: This is the “Zombie Burner” scenario. If the contact weld is severe enough, it bypasses the “Off” cam entirely. This is an emergency. You must cut power at the breaker immediately. The knob is physically disconnected from the circuit by the weld.

Q: Does this happen more often on Glass Tops or Coil Stoves?

A: It is equally common on both, but the symptoms are scarier on Glass Tops. Because the glass retains heat, a thermal runaway can actually crack the ceramic glass surface if a heavy pot traps the heat for too long.